Cooling Tower Replacement: Water Quality and Control

Dec 05, 2025Cooling tower replacement is something most facility teams eventually face, especially when water quality becomes harder to control or the tower no longer performs the way it should. In our experience, operators usually notice the small changes first. The cooling capacity is not what it used to be, the energy draw climbs a little higher each year, or the equipment needs more attention than the staff can reasonably keep up with. These early signs often point to deeper issues within the cooling system.

This overview will walk you through the key considerations we usually share when a team is deciding what to do next. It’s meant to help you understand the condition of your tower, how cooling needs evolve over time, and what factors influence long-term performance and reliability.

Why Facilities Consider Cooling Tower Replacement

Teams usually start discussing cooling tower replacement when the tower no longer handles heat the way it used to. Performance drops slowly at first, especially in older towers, then the repair cycle becomes constant. We have seen facilities patch the same issues month after month, only to watch the cost of keeping the system running climb higher than expected. At some point, tower replacement becomes the more responsible option simply because the equipment can no longer meet the load without excessive downtime.

Corrosion is another common trigger. Once the structure weakens or the fill begins to collapse, the tower’s efficiency slips and the system works harder to compensate. The repair effort quickly adds up. Many facilities discover that by the time they add labor, parts, and lost cooling performance to the equation, a full replacement provides better long-term stability than continuing to repair a failing system.

Water Quality and Direct Contact Cooling Challenges

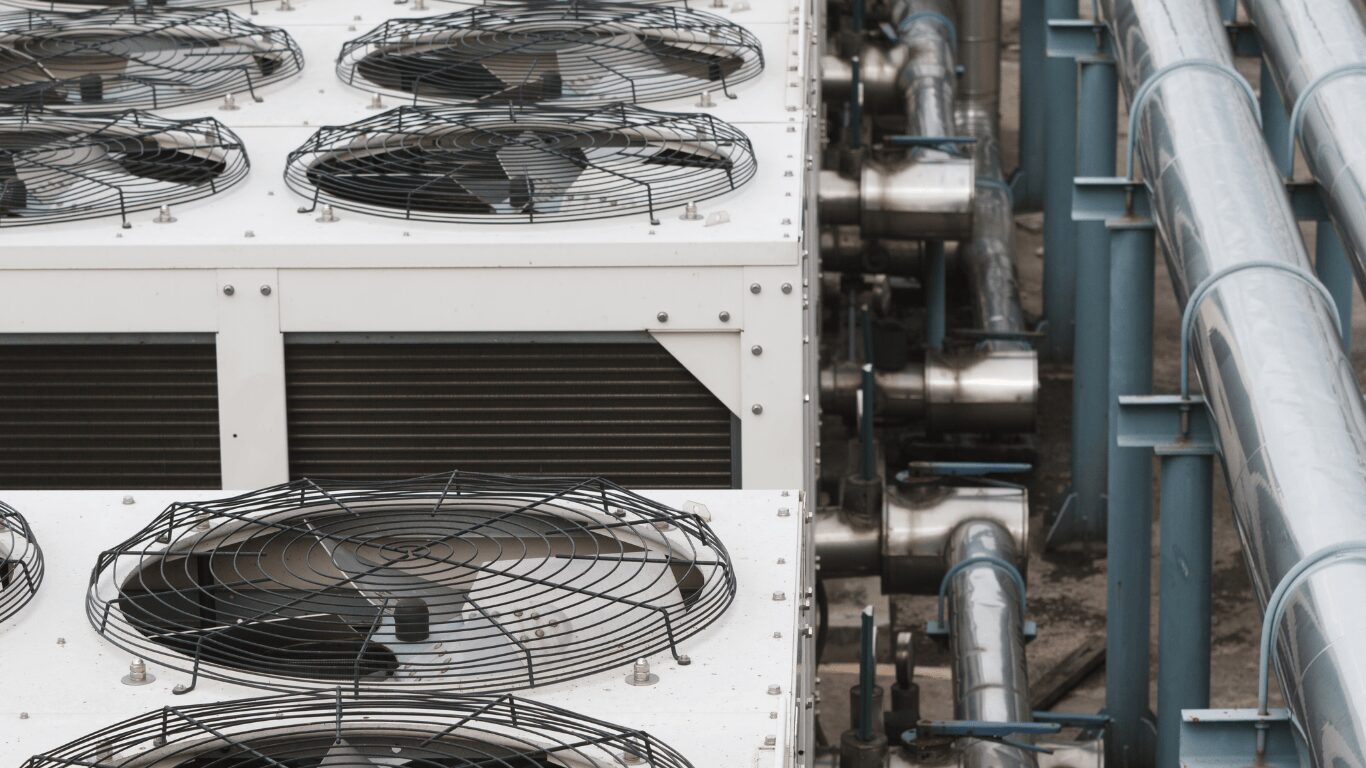

When operators ask us why their cooling tower struggles long before its expected service life, water quality is often the first place we look. A cooling tower works through direct contact between water and air, and that process exposes every surface to minerals, debris, and biological growth. Poor control lets these contaminants settle into the fill, which restricts flow and forces the fans to work harder just to move the same amount of air. Over time, corrosion sets in and the entire cooling tower loses efficiency.

Open circuit cooling towers feel these effects more than most because they constantly cycle in fresh water that brings new impurities with it. Without consistent treatment, the tower’s drift eliminators get coated, the basins foul quickly, and operators notice a steady decline in performance. If you want a deeper look at how treatment influences long-term performance, we often guide teams to our resource on cooling tower treatment, which explains how proper chemistry keeps equipment cleaner and running better.

Assessing Your Cooling Tower

Deciding whether to repair, refurbish, or replace a cooling tower begins with a detailed look at the system and its components. Understanding the condition of each part helps teams determine the most efficient path forward and avoid wasted effort on temporary fixes.

- Inspecting motors and pumps is crucial, as signs of strain here often indicate that the unit is struggling to maintain proper operation.

- Fill and drift eliminators should be evaluated next, because fouled or damaged materials reduce airflow and heat transfer, limiting overall tower efficiency.

- Fans and air inlet louvers also impact performance, and even small blockages or wear can make the system work harder than necessary.

- Maintenance records provide insight into recurring issues; towers that demand constant repair usually signal that the underlying structure or components are nearing the end of their service life.

- Comparing the existing unit’s condition with the cost of repair or refurbishment helps teams determine whether a full replacement will achieve more reliable, long-term operation.

For operators looking to understand how performance losses occur and what can still be recovered, our guide on cooling tower efficiency is a helpful resource.

Planning a New Cooling Tower or Upgrade

A new cooling tower should fit the facility you have today and the one you expect to operate years from now. This planning phase is where teams gain the most control over long-term performance, energy efficiency, and overall stability. Instead of focusing only on installation details, it helps to look at how the entire cooling system supports daily operation.

- The chiller plant is a good starting point because tower capacity and chiller performance are directly linked. A mismatch here often shows up as poor cooling during high-load periods.

- Air conditioning and process requirements should be reviewed together, since manufacturing lines, tenant changes, or new equipment can push heat rejection higher than older designs can handle.

- Modern towers offer better control of airflow and water distribution, which improves energy efficiency and keeps the equipment from working harder than necessary.

- It also helps to evaluate the condition of existing fill, especially if the team has dealt with fouling or uneven water distribution. For those exploring upgrades, our guide on cooling tower fill replacement gives a clear look at how material changes affect performance.

- Teams planning a new tower should tie every decision back to project goals. That includes future load expectations, operating conditions, and the way the cooling system integrates with other units in the facility.

Cost Considerations and Alternatives

Evaluating the cost of a cooling tower replacement isn’t just about the upfront price; long-term value often tells a different story. Teams should weigh the expense of a new tower against ongoing maintenance, energy use, and potential downtime. In some cases, a refurbished tower offers a practical alternative, providing reliable performance at a lower initial cost while extending service life.

It’s important to look at examples from similar projects. One facility we worked with chose a cheaper, refurbished tower to save money, but they also invested in upgraded fill and fans to ensure efficient operation. Compared to continuing repairs on their older tower, this alternative reduced downtime and energy costs while keeping the system stable.

Teams often overlook hidden costs like frequent maintenance, lost productivity, or higher utility bills when budgeting. Being responsible means factoring in these elements to achieve a balance between cost savings and long-term reliability.

Planning a Smooth Cooling Tower Replacement

Replacing a cooling tower is about aligning the project with your facility’s goals and ensuring the system operates efficiently from day one. Teams should start by reviewing how the tower integrates with existing chiller plants, pumps, and fans to optimize heat removal without overloading power systems. Proper control of water flow, airflow, and system operation ensures that the new tower achieves its designed efficiency and performance.

Breaking the project into clear steps helps avoid surprises. Define project goals early, including load requirements, maintenance accessibility, and energy targets. Evaluate each piece of equipment and its role in the system, and coordinate timelines to minimize downtime for commercial operations. Attention to these details not only preserves efficiency but also highlights the advantages of a well-planned replacement compared to reactive repair cycles.

Need guidance on replacing a cooling tower while maintaining reliable operation and reducing long-term costs? Connect with us to discuss strategies tailored to your facility’s needs.

Frequently Asked Questions (FAQs)

What factors determine if a tower repair is enough or a full replacement is needed?

Teams usually assess the age of the tower, the condition of critical components like pumps, motors, and fill, and the frequency of required maintenance. If repeated repairs are needed or efficiency continues to drop, replacement is often the more cost-effective and reliable option.

How can equipment upgrades extend the service life of a cooling tower?

Upgrading components such as drift eliminators, fans, or control devices can improve efficiency and reduce wear on other parts. These improvements often allow towers to operate closer to original specifications, delaying full replacement while maintaining reliable performance.

Are there alternatives to replacing a tower in a commercial building?

Refurbished towers or partial component replacements can be effective alternatives, especially for facilities with many cooling towers. One example is a manufacturing plant that replaced only the fill and motors, achieving near-new performance without the cost of a full replacement.

What role does proper water and heat control play in cooling tower efficiency?

Maintaining the right water quality and regulating heat removal ensures the system operates efficiently. Poor control accelerates corrosion and component wear, reducing service life and increasing operational costs.

Does a new cooling tower come with a warranty, and what should facilities check?

Most new towers include a manufacturer’s warranty covering key components. Facilities should review coverage for pumps, motors, fill, and structural elements, and ensure installation follows recommended principles to protect long-term performance.