Reverse Osmosis Storage Tanks: Design and Sizing

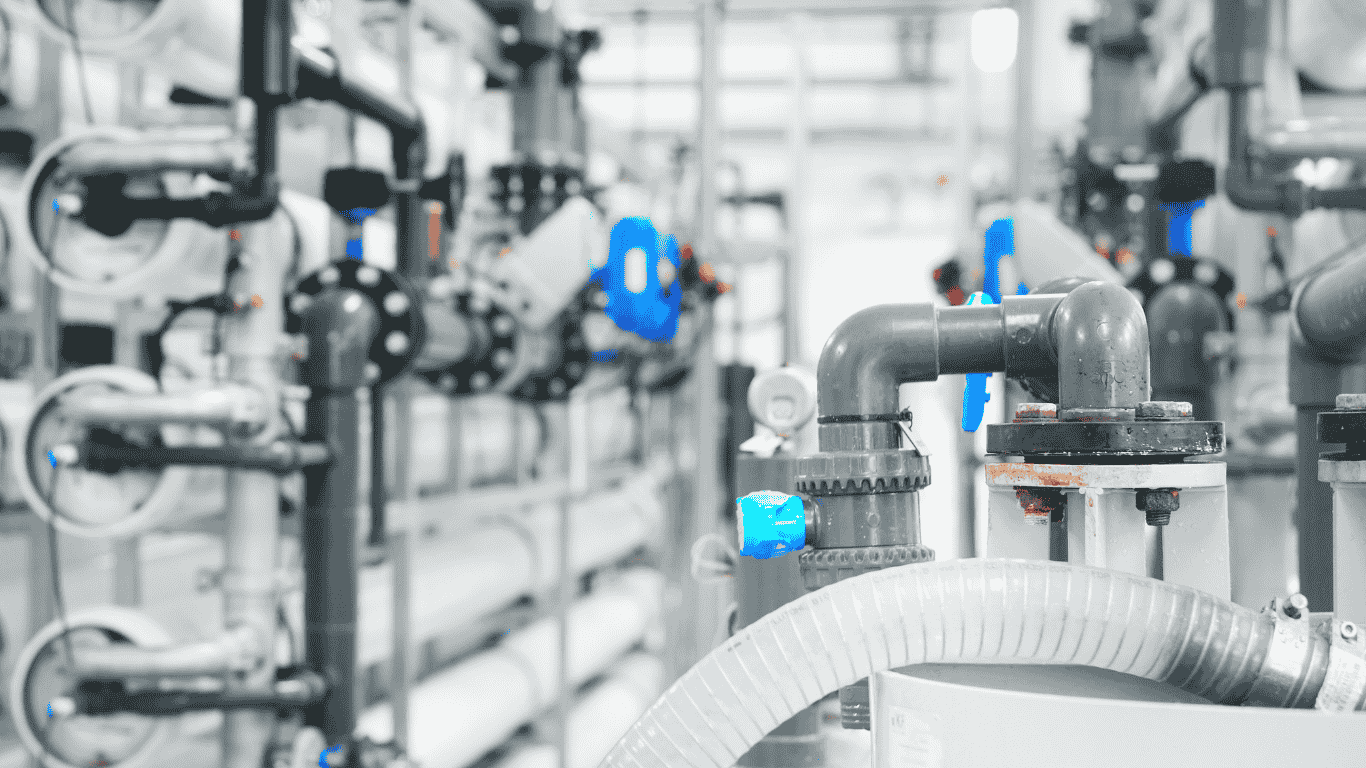

Jan 20, 2026When teams talk about reverse osmosis, the focus usually lands on membranes, pumps, and rejection rates. That is understandable, but in real-world operation, performance often depends just as much on what happens after treatment. A reverse osmosis tank is not an add-on or a convenience feature. It is a working part of the system that keeps production stable and water available when demand changes.

We have seen well-designed reverse osmosis installations struggle simply because water storage was treated as an afterthought. Without adequate storage, even a high-performing system can fall short when operators need consistent flow or immediate access to water. Proper water storage helps balance production and demand, protects equipment, and supports reliable operation across the entire system.

What a Reverse Osmosis Tank Actually Does

At its core, a reverse osmosis tank acts as a buffer between water production and water use. A reverse osmosis system produces water at a steady rate, but facilities rarely use water that way. Demand comes in waves. The storage tank absorbs those fluctuations by holding treated water so it is available when operators open a valve, start a process, or increase flow.

This buffering role is critical for maintaining stable pressure. Without adequate storage, the system is forced to start and stop frequently to keep up with demand. That short cycling increases wear on pumps and membranes and often leads to inconsistent delivery pressure at points of use. A properly sized water storage tank smooths out those swings and allows the system to run in its optimal operating range.

There is also a direct connection to water quality. Consistent operation helps membranes perform as designed, which improves rejection and reduces fouling risk. When a storage tank is integrated correctly, it protects the reverse osmosis tank investment by supporting stable operation, preserving membrane life, and delivering consistent water quality throughout the facility.

How Storage Improves System Stability and Output

One of the clearest advantages of adding storage is how much calmer the entire reverse osmosis operation becomes. When a tank is doing its job, the system no longer has to react to every sudden change in demand. Instead, it runs steadily and predictably, which is exactly how RO equipment is designed to operate.

- Storage provides a reserve of treated water, so operators can draw more water instantly without forcing the system to ramp up on the spot. This is especially important during peak usage periods when demand briefly exceeds production capacity.

- A properly sized tank helps maintain consistent water pressure at points of use. Rather than seeing pressure drop every time flow increases, the system stays balanced and responsive.

- By reducing rapid start and stop cycles, storage lowers mechanical stress on pumps and membranes. Over time, this steady operation helps extend equipment life and improves overall system reliability.

From a practical standpoint, a well-integrated tank lets reverse osmosis equipment do what it does best. It produces high-quality water at a controlled rate, while storage absorbs the ups and downs of real-world use. To learn more about how storage and system design work together, check out our guide on advanced filtration technologies for potable water systems.

Common Types of Reverse Osmosis Storage Tanks

Not all reverse osmosis storage tank designs solve the same problem, and choosing the right one depends on how the system is used. Over the years, I have seen facilities struggle simply because the storage style did not match their operating needs. Understanding the basic differences helps teams avoid that mismatch.

Atmospheric tanks are common in larger systems where higher volumes of RO storage are needed. These tanks are vented and typically paired with booster pumps to deliver water downstream. They work well when flexibility and scalability matter, especially in commercial and industrial applications where demand varies throughout the day.

Pressurized and bladder-style osmosis tanks are more compact and are often associated with residential or point-of-use applications. These tanks store drinking water under pressure, allowing water to be delivered directly to a faucet without additional pumping. While the product footprint is smaller, capacity is limited, which makes them best suited for low-demand systems rather than process-driven operations.

Sizing a Reverse Osmosis Storage Tank Correctly

Sizing is where most storage issues begin, and it is also where teams can make the biggest improvements. The goal is not to install the largest tank available, but to match capacity to how the system actually operates. That starts with understanding daily demand patterns, peak usage windows, and how quickly the RO unit can recover after drawdown.

When storage is undersized, the tank empties too quickly and forces the system to chase demand. Pressure drops, recovery time increases, and operators often compensate by pushing equipment harder than recommended. Oversizing creates a different problem. Excessive volume increases dwell time, which can affect water freshness and complicate level control, especially in systems with intermittent use.

We usually recommend starting with real usage data and working backward. Look at peak flow rates, required reserve volume, available footprint, and tank height limitations. From there, teams can select a size that supports stable operation without wasting space or creating downstream water management challenges.

Materials, Construction, and Certifications

The material a tank is built from plays a major role in long-term performance and water quality. Most reverse osmosis storage tanks are constructed from polyethylene, fiberglass, or steel, each with its own strengths. What matters most is that the material is compatible with treated water and designed to resist corrosion, leaching, and structural fatigue over time.

Durability is not just about thickness or weight. A well-built tank includes smooth interior surfaces, proper coatings, and sealed access points that protect against contamination. These details are easy to overlook, but they directly affect how clean the stored water remains and how long the tank will last in service. In high-use systems, small construction shortcuts often show up as quality problems later.

Certification is another area where teams should not compromise. NSF certified tanks provide documented assurance that the materials and construction meet drinking water standards. That certification adds an extra layer of protection for water quality and gives operators confidence that the storage component supports, rather than undermines, the overall treatment process. To see how material and tank design fit into broader water treatment strategies, visit our guide on water treatment technologies.

Installation Considerations Operators Often Miss

Installation details tend to get rushed, but this is where long-term headaches usually start. I always tell operators to think beyond getting the tank in the room and focus on how it will be used and inspected years from now. Simple planning upfront makes daily operation much easier.

Access is the first thing to check. Teams need enough clearance around the tank for inspection, cleaning, and future service. Tight installations may save floor space, but they often limit visibility and make routine work harder than it needs to be. Location also matters. Placing the tank near points of use can reduce piping complexity and help maintain consistent water delivery.

Color is another overlooked detail. White tanks are easier to inspect because operators can quickly spot sediment, discoloration, or biofilm formation. Clear visual cues help teams catch problems early, which protects water quality and keeps the system operating as intended.

Storage Tanks in Broader Water Treatment Strategies

Reverse osmosis storage tanks do more than hold water. They are a key part of managing an entire facility’s water strategy. By integrating storage effectively, operators can balance supply with demand, maintain consistent water quality, and reduce stress on the system. A tank that is sized and located thoughtfully allows the RO system to operate efficiently while supporting downstream processes.

Storage also plays a role in sustainability. When water is stored and managed correctly, facilities can reduce waste, reclaim more water, and optimize reuse opportunities. For teams looking to see this in action, our guide on sustainable water treatment outlines practical strategies that complement RO storage systems.

Finally, considering storage within the broader system context helps teams plan for water source variations, treatment sequencing, and long-term operational efficiency. For an overview of how storage fits into overall water treatment solutions, check out our article on water treatment technologies. Proper integration ensures that reverse osmosis tanks support consistent water quality while protecting both equipment and downstream processes.

Operating Costs, Pricing, and Long-Term Value

Cost is often the first factor teams look at when selecting a reverse osmosis storage tank, but it should not be the only one. The initial price can vary widely depending on size, material, and certifications, yet choosing the cheapest option often leads to higher long-term expenses due to maintenance, replacement, or performance issues.

Stock availability is another practical consideration. A tank that is readily available reduces downtime and keeps the system running smoothly, whereas backordered products can delay installation or upgrades. When planning a purchase, make sure the product you select meets capacity and durability needs rather than simply picking what is easiest to add to a cart.

Operators should also factor in lifecycle cost. A well-built tank may have a higher upfront cost but provides better protection, longer service life, and consistent water quality. When it’s time to order, consider both immediate price and total value to avoid costly surprises down the line.

Where Expert Guidance Makes the Difference

Even with a clear understanding of tank types, sizing, and materials, getting the most out of a reverse osmosis system often comes down to proper integration. Teams frequently run into issues when storage is added without considering flow patterns, system recovery rates, or downstream processes. These oversights can reduce water quality, stress equipment, and increase long-term costs.

Experts can recommend solutions tailored to your specific water use, facility layout, and production needs. They help identify the right tank size, placement, and connections, ensuring the system operates efficiently while avoiding common pitfalls. This guidance is particularly valuable for customers managing multiple points of use or high-demand applications, where small mistakes can have large impacts.

Want to prevent costly mistakes and maximize your RO system’s lifespan? Talk to our experts, and we’ll help tailor a water storage plan that fits your facility’s real-world needs.

Frequently Asked Questions (FAQs)

What regular maintenance does a reverse osmosis tank require?

Maintenance is mostly about keeping the tank clean and ensuring connections remain leak-free. Operators should check the pressure periodically and inspect the tank for sediment or discoloration. In high-use systems, flushing or sanitizing the tank may be necessary to protect water quality and extend the life of the tank and system.

How do I determine the right tank size for my facility?

Selecting the correct tank size depends on daily water demand, peak usage, and system recovery rate. Oversizing can lead to stale water, while undersizing may stress the RO system. Reviewing your usage patterns and consulting an expert can help you choose the optimal size to balance efficiency and availability.

Can residential reverse osmosis tanks handle drinking water storage safely?

Yes, properly designed residential tanks are built for drinking water use. Look for tanks that are NSF certified, made from food-grade materials, and properly maintained. These measures ensure the water remains clean and safe for household use.

What should I do if my RO storage tank loses pressure or leaks?

If you notice a drop in pressure or visible leaks, it’s important to isolate the tank and check connections. Many issues can be fixed by adjusting pre-charge pressure or replacing faulty components. Always follow the manufacturer’s guidelines and consider having a professional inspect the system to prevent further problems.

How can I get support or replacement parts for my RO storage tank?

Most manufacturers and suppliers provide support via email, phone, or online portals. Make sure you have the tank model, purchase date, and any relevant documentation handy. This information helps the team identify the right replacement parts or schedule service, ensuring your tank continues to function reliably.