Steam Quality: Improving Efficiency with Water Treatment

Jul 29, 2025Why Steam Quality Matters

Steam plays a central role in energy transfer across industrial and commercial systems. It’s used to power heat exchangers, drive sterilization, regulate process temperatures, and maintain comfort in large-scale buildings. But when steam isn’t properly managed, the system pays for it – sometimes literally.

Steam quality refers to the ratio of vapor to liquid within a steam sample. In high-quality steam, most of the energy exists as latent heat, carried in dry, saturated vapor. When moisture in the steam increases, that energy potential drops, often without operators realizing it. The result? Longer heat-up times, lower output temperatures, and premature wear on system equipment.

Low steam quality also creates significant problems for specific applications. In steam sterilizers, even slight reductions in dryness can prevent proper decontamination. In industrial steam systems, moisture can damage steam traps, foul lines, and reduce overall system efficiency.

Many facilities assume steam is “working” if heat is being delivered – but poor-quality steam doesn’t announce itself until cycles slow down, utility bills spike, or equipment starts failing. That’s why understanding and managing steam quality is critical for any operation that relies on thermal energy.

See how Boiler Water Treatment supports high steam quality by preventing carryover and system fouling.

What Is Steam Quality?

What Is Steam Quality?

In simple terms, steam quality is a measure of how much of a steam sample is usable vapor versus entrained water droplets. It’s usually expressed as a percentage. A 100% quality steam sample means all vapor – no moisture. A 90% quality sample means 10% is liquid water, which can impact energy transfer, corrosion, and mechanical wear.

There are three common categories of steam:

- Saturated steam – steam in equilibrium with liquid water; the most common and effective for heating

- Wet steam – steam that carries liquid water; caused by poor separator performance, carryover, or system design

- Superheated steam – vapor heated beyond saturation point; used in turbines, but less effective for direct-contact heating

Dry saturated steam delivers maximum latent heat to the process. But as steam condenses or picks up moisture in the system, its ability to deliver energy drops – often without operators noticing until performance falls off.

How Steam Quality Is Measured

Measuring steam quality is essential for verifying performance, especially in systems where precision matters – like steam sterilization, food production, or sensitive process heating. Poor steam quality often goes unnoticed until downstream performance suffers or system components begin to degrade.

Steam quality is defined by the percentage of vapor in a steam sample. A reading of 100% steam quality means all vapor, with no suspended water droplets. A 90% reading indicates that 10% of the mass is water, which reduces heat delivery and increases wear.

The most widely accepted method for field measurement is calorimetric testing. This approach evaluates the latent heat available in a sample and compares it to the expected energy content based on system pressure and temperature. Some facilities may use temperature sensors, conductivity meters, or infrared cameras to spot red flags, but these tools don’t directly measure quality – they only highlight symptoms.

Facilities regulated by groups such as ASHE (American Society for Health Care Engineering) or state environmental agencies may be required to provide proof of steam quality standards, particularly when equipment is being used for sterilization or pharmaceutical-grade heating.

In healthcare settings, steam sterilizers must meet precise standards to be considered compliant. Protocols like ANSI/AAMI ST108:2023 define acceptance criteria for steam purity, dryness, and non-condensable gas content – each critical to ensuring effective sterilization without damage to instruments or risk to patients.

In general, when steam achieves above 95% quality rating is when it’s considered acceptable for most industrial applications. Anything lower may lead to poor heating, cycle delays, and inadequate air removal in systems like steam sterilizers.

What Causes Poor Steam Quality?

Several variables can lead to low steam quality – and most trace back to issues in the boiler or water treatment program. Common causes include:

- Boiler water carryover, often due to high TDS (total dissolved solids) or foaming

- Improper blowdown practices, which allow impurities to accumulate and entrain with the steam

- Sudden pressure drops in the steam line, which cause the steam to flash into a mix of vapor and liquid

- Water chemistry imbalances that promote scaling or deposit formation

- Insufficient or poorly functioning separators or steam traps

Boiler operation plays a huge role. A stable firing rate, clean water, and proper chemical treatment help maintain the dryness of the steam. Without this, moisture levels increase – leading to wet steam, energy loss, and corrosion risk throughout the steam system.

See how Oxygen Scavengers Support Boiler Water Treatment and help protect against corrosion and carryover that degrade steam quality.

How Poor Steam Quality Affects System Performance

Low steam quality doesn’t just mean wasted energy – it leads to measurable losses in throughput, higher maintenance costs, and reduced equipment life. Even small increases in entrained moisture can degrade the performance of heat transfer components, contribute to premature failure of steam traps, and leave water droplets in systems never designed to handle liquid.

Poor steam quality typically shows up as:

- Longer heat-up times or inconsistent process temperatures due to poor heat transfer

- Accumulation of condensate in steam supply lines

- Equipment failure in valves, control devices, or sterilizer chambers

- Premature corrosion caused by carbon dioxide and dissolved oxygen

- Imbalances in boiler combustion due to unstable pressure or moisture cycling

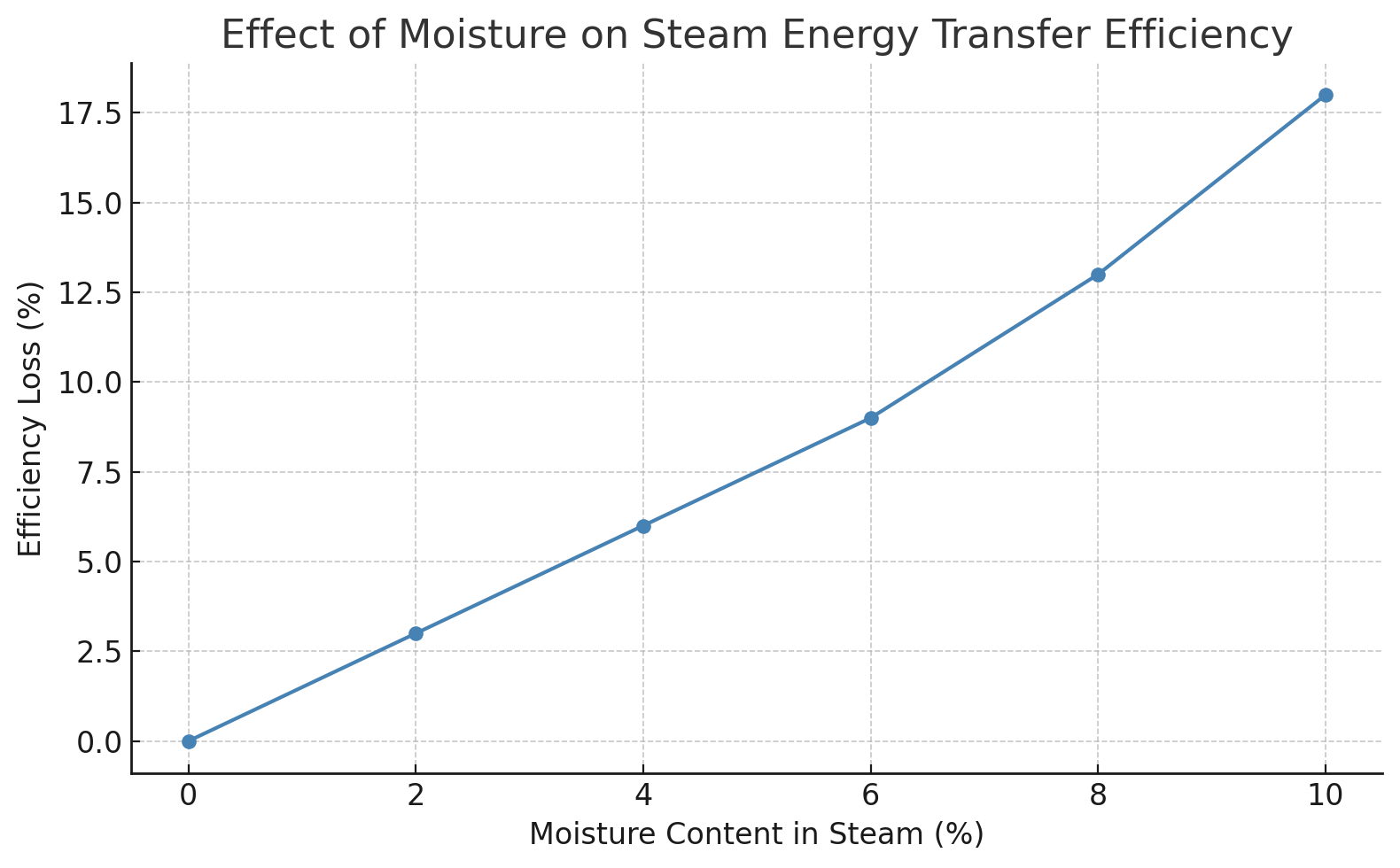

In every case, wet steam means less useful energy. The system has to work harder, and wear occurs faster. The chart below illustrates the general trend between increased moisture content and efficiency loss – based on widely accepted thermodynamic behavior in saturated steam systems.

For illustrative purposes only. Trend reflects widely accepted engineering principles on moisture-related energy loss in steam systems.

In many industrial facilities, these problems are accepted as “normal wear and tear” – until the maintenance log or energy bill tells a different story.

High-Impact Applications That Depend on Steam Quality

While every system benefits from dry steam, certain applications are particularly sensitive to moisture:

- Steam Sterilizers: In healthcare and pharma, poor steam quality leads to inadequate air removal, reduced penetration, and failed sterilization cycles. This compromises safety and puts compliance at risk.

- Process Heating in Manufacturing: From food and beverage to chemical processing, steam that delivers less latent heat means more runtime to achieve the same temperature – leading to higher energy use and reduced throughput.

- HVAC and Commercial Buildings: In large buildings, wet steam contributes to inconsistent temperatures, heat imbalance, and system wear – especially in buildings using pressure reducing valves or multi-zone distribution systems.

Case Example: Sterilizer Downtime in a Healthcare Facility

A regional hospital was experiencing recurring delays in its steam sterilization process. Despite proper system pressure and water treatment protocols, several sterilizer chambers were failing routine validation. Upon inspection, engineers identified elevated moisture in the steam, traced back to minor but cumulative pressure drops in the steam supply line feeding the sterilizers.

Because steam wasn’t reaching the correct latent heat threshold, cycles required more time to achieve the desired temperature – or failed altogether due to inadequate air removal. The problem was eventually traced to undersized traps and high TDS carryover from inconsistent boiler blowdown.

This kind of issue doesn’t always trigger alarms – but it costs real time, increases maintenance load, and introduces compliance risk in healthcare and industrial steam systems alike.

Read how Optimizing Boiler Efficiency for Commercial Buildings reduces steam waste and improves reliability across campus systems and multi-building properties.

How to Improve Steam Quality Through Water Treatment

Correcting low steam quality starts at the boiler. Poor-quality steam is often a symptom of deeper problems: contaminated feed water, improper blowdown, or chemical programs that aren’t calibrated to the system’s demands.

Key water treatment strategies to improve steam quality include:

- Controlling total dissolved solids (TDS) to prevent carryover into the steam line

- Using oxygen scavengers to reduce corrosive gas content in the boiler water

- Applying anti-foaming agents and dispersants to reduce water film instability

- Regular boiler blowdown to remove sediment and maintain pressure balance

- Ensuring proper pre-treatment via softeners or dealkalizers for incoming water

Chemistry is only part of the equation. Mechanical factors – like steam separators, trap sizing, and pressure control – also affect steam dryness. But none of it works without a stable water chemistry foundation.

Learn how Oxygen Scavengers Improve Steam System Performance and support dry, stable energy delivery.

How R2J Helps Facilities Maintain High Steam Quality

R2J works with commercial, industrial, and institutional facilities across Florida to design treatment programs that deliver consistent, high-quality steam – no guesswork required.

Our services include:

- Full-system audits to identify steam quality weak points

- Customized chemical treatment plans built around system pressure, demand, and fuel type

- Installation and support of chemical feed systems and pre-treatment equipment

- Scheduled testing for TDS, conductivity, oxygen, and key boiler water metrics

- On-site technical support to adjust programs based on seasonal or usage changes

Every treatment plan is tailored – not just to the boiler itself, but to how the steam is being used. That’s how we help customers eliminate waste, improve heat delivery, and extend the life of their equipment.

Frequently Asked Questions

What is considered acceptable steam quality?

Most systems should maintain steam quality of 95% or higher. Some critical applications, like sterilization, may require >97%.

How is steam quality different from steam pressure or temperature?

Pressure and temperature describe the system environment; steam quality reflects how much usable energy (latent heat) is available.

Can poor steam quality cause equipment failure?

Yes. Moisture can lead to water hammer, erosion, corrosion, and premature wear on traps, valves, and control systems.

How often should steam quality be tested?

At least annually, or more often in high-sensitivity systems. Testing is also recommended after major system changes or shutdowns.

Does water treatment alone fix steam quality?

It’s a major part of the solution – but mechanical design, trap health, and proper operation must support it.

Protecting Your Steam System Starts at the Water

Steam quality isn’t just about comfort or consistency – it’s about energy, safety, and cost. When your system produces high-quality steam, everything downstream performs better.

R2J helps facilities optimize their steam systems from the ground up, with chemistry, control, and testing programs built to protect pressure, temperature, and throughput.

Contact us today to schedule a system review and start delivering cleaner, drier, more efficient steam.