Boiler Water Testing: Essential Corrosion Guide

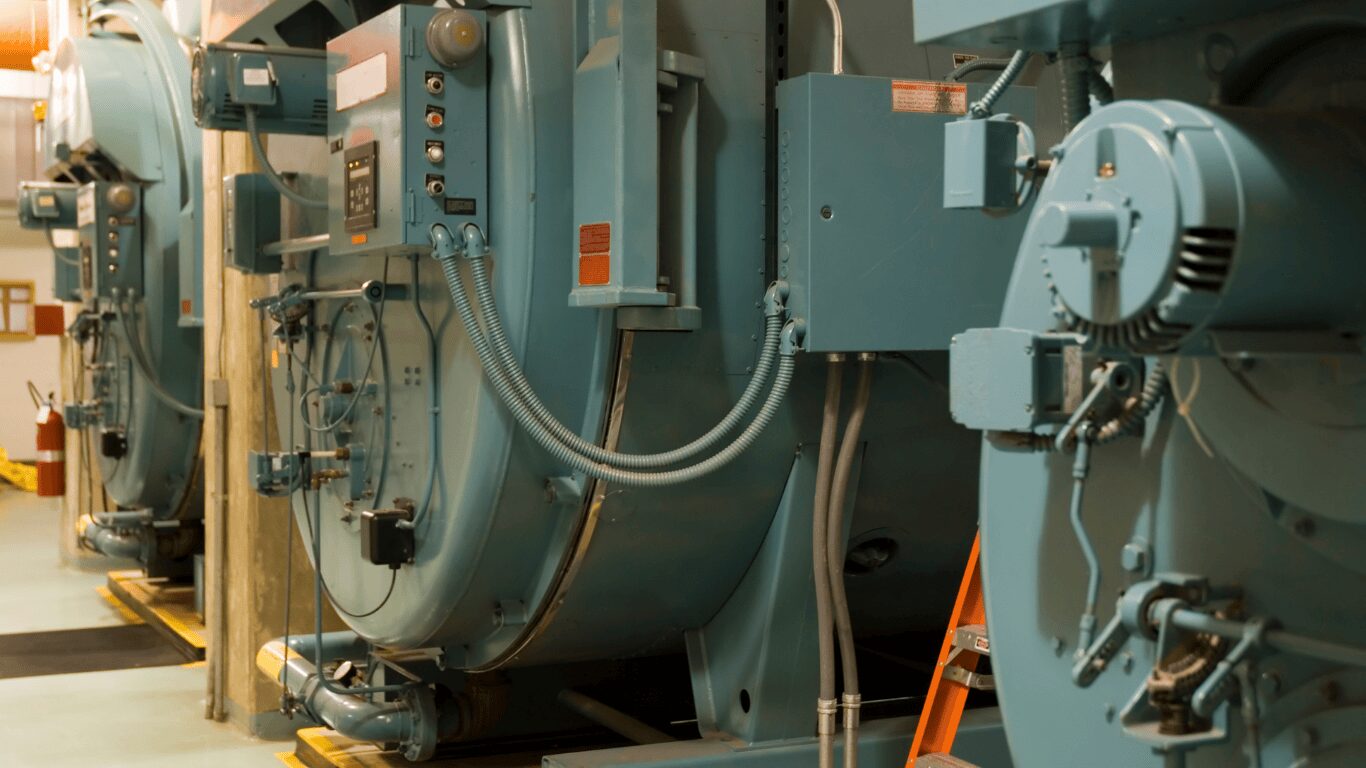

Nov 14, 2025Boiler water testing is essential for keeping steam boilers safe, efficient, and long-lasting. Boiler water contains minerals, dissolved oxygen, and other impurities that, if unmanaged, can cause corrosion, scale formation, and reduced heat transfer efficiency. Regular testing protects metal surfaces, prevents costly damage, and ensures your boiler system operates reliably.

In this article, we’ll explore the fundamentals of boiler water, common issues like acidic corrosion and high total dissolved solids, key testing parameters, methods and tools, and effective treatment approaches.

Understanding Boiler Water

Boiler water is the lifeblood of any steam boiler system. As mentioned earlier, it carries dissolved minerals, gases, and other impurities that directly affect boiler performance and longevity. One key factor is dissolved oxygen, which can accelerate corrosion on metal surfaces if left unchecked. High total dissolved solids (TDS) increase the risk of scale formation, reducing heat transfer efficiency and stressing boiler tubes.

Maintaining proper alkalinity balances the water’s pH, preventing acidic corrosion and caustic embrittlement. Regular monitoring of these parameters ensures consistent boiler water quality, protects the system from damage, and supports safe, efficient steam production. Understanding the chemistry of boiler water is the first step in preventing costly failures.

Common Boiler Water Issues

Boiler water can cause several problems if not monitored and treated properly. Operators often encounter:

- Corrosion – This includes acidic corrosion and caustic embrittlement, which weaken metal components, increase repair costs, and can even lead to catastrophic failures.

- Scale formation – Dissolved minerals precipitate onto boiler tubes and heat exchange surfaces, acting as an insulator. This reduces heat transfer efficiency and forces the system to consume more energy.

- Suspended solids – Particles in the water can settle in tubes or valves, causing blockages, localized overheating, and mechanical stress that shortens equipment life.

Addressing these issues early through consistent boiler water testing protects your system, maintains efficiency, and extends boiler longevity.

Key Parameters in Boiler Water Testing

Maintaining proper boiler water chemistry starts with understanding its key parameters. A thorough boiler water test evaluates several critical factors:

- pH level – Measures acidity or alkalinity to prevent corrosion or caustic embrittlement.

- Boiler water alkalinity – Ensures the water can neutralize acids and maintain stable chemistry.

- Dissolved oxygen – High oxygen levels accelerate metal corrosion, so monitoring is crucial.

- Total hardness – Hard water minerals contribute to scale formation on boiler tubes.

- Total dissolved solids (TDS) – Excess TDS increases risk of scaling and reduces heat transfer efficiency.

Boiler water testing services use lab analysis and on-site tools to measure these values, helping operators maintain each parameter within its target range for safe, efficient boiler operation.

Testing Methods and Tools

Ensuring your boiler water stays within the right chemistry ranges starts with using the right testing methods and tools. Operators rely on a combination of approaches to keep systems safe and efficient:

- On-site testing – Portable testing tools and conductivity meters allow for quick checks of pH, total dissolved solids, and other essential parameters.

- Laboratory testing – Detailed lab analysis identifies subtle issues in boiler water chemistry and verifies the effectiveness of treatments.

- Chemical dosing and treatment – Implementing chemical treatment and automated chemical dosing helps maintain consistent water quality and prevent corrosion or scaling.

- Continuous monitoring – Real-time sensors track water chemistry, giving early warnings before problems like scale formation or corrosion occur.

- Reverse osmosis – Treating makeup water through reverse osmosis removes impurities, protecting boiler tubes and improving overall system efficiency.

Boiler Water Treatment Approaches

Maintaining proper boiler water chemistry is about taking proactive steps to protect your system. Effective boiler water treatment combines chemical solutions and operational practices to prevent corrosion, scaling, and efficiency losses. Key strategies include:

- Oxygen scavengers – Reduce dissolved oxygen levels to prevent corrosion on metal surfaces.

- Corrosion inhibitors and scale inhibitors – Protect boiler tubes and heat exchange surfaces while reducing scale formation.

- Chemical treatment and dosing adjustments – Ensures consistent water quality and supports boiler efficiency in steam boilers and high pressure systems.

- Operational controls – Regular monitoring of parameters and treatment programs enhances system reliability and energy efficiency.

For a deeper dive into treatment strategies, check out our guide on effective boiler corrosion prevention.

Operational Practices to Maintain Water Quality

Keeping boiler water within safe parameters requires consistent operational practices alongside chemical treatment. Adjusting blowdown frequency and performing surface blowdown help control total dissolved solids and prevent scaling. Careful treatment adjustments and chemical dosing maintain water chemistry within safe limits, protecting metal components from corrosion.

Regular boiler water testing and continuous monitoring catch early issues, reducing repair costs and preventing costly downtime. These practices are especially important for systems with steam turbines, large boiler systems, or high-pressure operations, where water chemistry directly impacts performance and longevity.

For more detailed guidance on managing blowdown practices, see our article on boiler blowdown.

Building a Strong Boiler Maintenance Plan

Integrating boiler water testing into your preventive maintenance program is essential for keeping your system reliable and efficient. Start with regular testing schedules, consistent chemical treatments, and carefully monitored blowdown frequency. Routine inspections of metal components, boiler tubes, and other critical parts help catch early signs of corrosion, scaling, or wear before they affect performance.

For practical tips on maintaining equipment and water chemistry, teams often consult resources like our guide on industrial boiler maintenance.

Next Steps

Following these practices supports system efficiency, optimizes energy use, and ensures safe operation under your facility’s operational demands.

Need guidance creating a tailored maintenance program? Our experts at R2J can help you improve efficiency, extend equipment life, and keep your system safe.

Frequently Asked Questions (FAQs)

What is the role of water treatment in boiler systems?

Water treatment ensures boiler water remains within safe chemical limits, preventing corrosion, scale, and efficiency losses. Proper treatment protects equipment and maintains reliable operation across all boiler types.

How do dissolved gases affect boiler performance?

Gases such as oxygen and carbon dioxide can accelerate corrosion on metal components. Regular testing of oxygen levels and using chemical treatments like oxygen scavengers reduces this risk.

Why is makeup water important for boilers?

Makeup water replenishes the system as steam is used. Treating it through reverse osmosis or filtration ensures consistent water quality and prevents scaling or contamination.

What are phenolphthalein alkalinity and total alkalinity?

These measurements indicate the water’s buffering capacity, helping maintain proper pH and prevent acidic corrosion or caustic issues.

How often should water quality testing be performed?

Regular water quality testing identifies common boiler water issues such as high dissolved solids, corrosion, or scale before they cause costly damage.