Stainless Steel Passivation in Water Treatment Systems

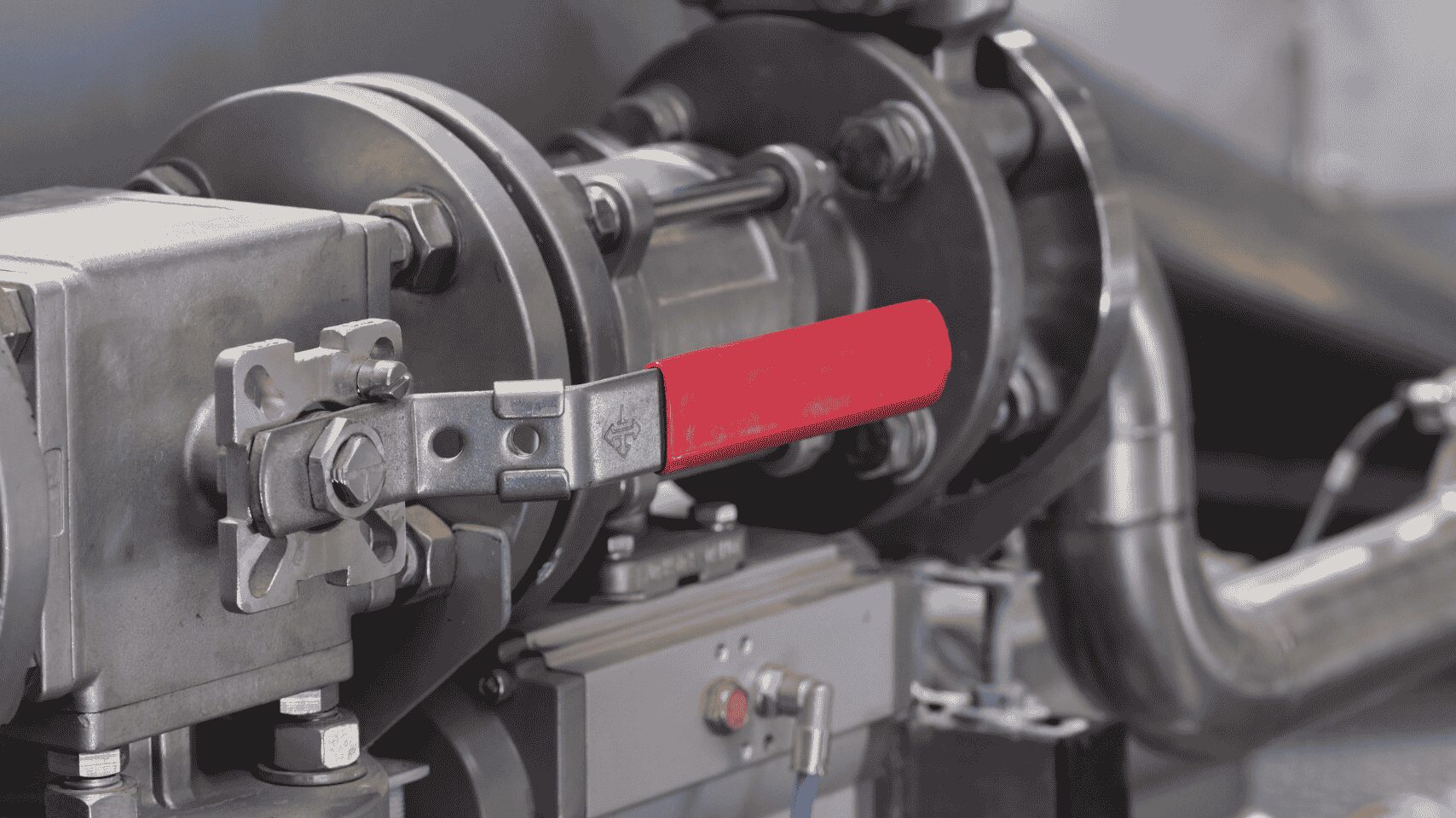

Feb 02, 2026In water treatment systems, stainless steel shows up everywhere. You see it in piping, tanks, heat exchangers, and fittings where reliability matters. Many teams assume stainless steel can take care of itself, but in real operating environments, that assumption leads to problems. Exposure to water chemistry, fabrication residue, and day-to-day handling can leave the surface vulnerable long before corrosion becomes visible.

This is where stainless steel passivation plays a critical role. Passivation is not about changing the material. It is about restoring and strengthening the surface so the metal can perform as intended. When done correctly, it supports corrosion resistance, protects system components, and helps extend equipment life across water treatment systems.

Operators who understand how surface conditions affect stainless steel are better equipped to prevent premature failure. Ignoring passivation often means reacting to rust, leaks, or contamination later, when the cost and risk are much higher.

What Passivation Really Means for Stainless Steel

Passivation is often described as a chemical treatment, but in practice, it is a surface conditioning step that allows stainless steel to behave the way it was designed to. During fabrication, installation, or maintenance, the metal surface can pick up residues that interfere with its natural ability to protect itself. The goal of passivation is to remove those unwanted contaminants and give the material a clean starting point.

In the passivation of stainless steel, the focus is not the bulk metal but the outermost layer that interacts with water and air. The passivation process uses controlled chemistry to clean the metal surface and encourage the formation of a stable passive layer. This invisible layer acts as a barrier, limiting how easily corrosive elements can reach the underlying metal.

When passivation is done correctly, corrosion resistance improves without altering the strength or structure of the material. Operators often think of it as insurance for stainless steel components. It does not make the metal indestructible, but it significantly reduces the likelihood of surface-driven corrosion that can shorten equipment life or compromise system performance.

Why Stainless Steel Still Corrodes Without Proper Passivation

One of the most common misconceptions we hear in the field is that stainless steel is rust proof. In controlled conditions, it performs extremely well, but real systems are rarely controlled. During fabrication and installation, the material is exposed to iron from cutting tools, grinding wheels, and other metals in the shop environment. These steps introduce surface contamination that does not belong on stainless steel.

The machining process is a frequent source of trouble. Cutting, drilling, or polishing can smear iron across the surface or embed free iron into the metal. Even brief contact with carbon steel tools or worktables is enough. Once the system is placed into service, that iron reacts with water and oxygen, and rust begins to form, even though the base material is stainless steel.

From an operator’s perspective, this kind of corrosion often feels unexpected. The stainless steel itself did not fail. The surface did. Without proper passivation, those contaminants remain active and create localized corrosion sites. Over time, small rust spots turn into larger maintenance issues that could have been avoided with proper surface treatment early on.

The Role of Chromium and the Protective Oxide Layer

What makes stainless steel different from other metals is its chromium content. Chromium reacts quickly with oxygen to form chromium oxide on the surface of the metal. This reaction happens naturally, and it is the reason stainless steel can be corrosion resistant in demanding environments. The key is that this reaction must be allowed to happen cleanly and evenly.

The chromium oxide that forms is a very thin film, but it is highly effective. This oxide layer seals the surface and blocks oxygen and moisture from reaching the underlying metal. When the protective oxide layer is intact, it acts as a self-healing passive film. If the surface is lightly scratched, the film can reform as long as oxygen is present and the surface is free of contaminants.

Problems arise when the oxide layer is disrupted or prevented from forming properly. Embedded iron, shop residue, or improper handling interfere with this natural process. Passivation supports the formation of a uniform protective layer, allowing stainless steel to maintain its corrosion resistant properties over the long term without changing the base material.

Common Sources of Surface Contamination in Fabrication and Installation

Most passivation problems start long before a system is filled with water. Fabrication and installation expose stainless steel to surface contaminants that are easy to overlook in busy shop environments. Shop dirt, oils, and foreign matter settle on components during handling and storage, especially when stainless steel is processed alongside carbon steel or other metals.

Iron particles are one of the most damaging contaminants. Grinding dust, steel brushes, or shared work surfaces introduce exogenous iron onto the stainless surface. Even though this iron is not part of the parent metal, it becomes electrochemically active once the equipment is in service. Left untreated, these particles initiate localized corrosion that spreads beneath the surface.

Heat-related operations add another layer of risk. Welding and heat treating can create heat tint, which alters the surface chemistry and weakens the natural oxide protection. These discolored areas are more reactive and more prone to corrosion. Passivation addresses these issues by removing contamination and restoring the surface so it can form a stable, protective layer again.

Surface Preparation Before Passivation Begins

Effective surface passivation always starts with thorough cleaning. No passivation chemistry can work properly if oils, grease, or embedded debris remain on the metal. In practice, this means removing visible and invisible residues left behind from fabrication, handling, and storage before any acid treatment begins.

Alkaline cleaners are often used at this stage, with sodium hydroxide being a common choice for breaking down organic residues. This step lifts oils and shop soils without attacking the base metal. Once cleaning is complete, a water rinse is essential to flush away loosened contaminants. Many facilities rely on tap water for this step, but consistency and cleanliness matter. Poor rinsing can redeposit contaminants back onto the surface.

Skipping or rushing surface preparation is one of the biggest reasons passivation fails. Acid treatments are designed to condition a clean metal surface, not compensate for poor housekeeping. When cleaning is done properly, the passivation step that follows becomes predictable and effective, producing a uniform, corrosion-resistant surface.

Understanding the Chemical Passivation Process

Once the surface is properly prepared, chemical passivation treatments can do their job. At a high level, the passivation treatment involves exposing stainless steel to a controlled acidic environment that removes free iron and other reactive residues from the surface. This step does not coat the metal. It triggers a chemical reaction that allows the stainless steel to restore its natural protective behavior.

Most passivation methods rely on an acid bath where components are either immersed or circulated with solution. Immersion time matters. Too short, and contaminants remain. Too long, and the surface can be over-etched. The goal is balance. The process is designed to clean the surface selectively without damaging the base material.

After the acid exposure, the surface is rinsed thoroughly to stop the reaction and remove residual chemistry. At this point, oxygen from air or water helps rebuild the passive layer. When the process is controlled correctly, the result is a clean, stable surface that resists corrosion far better than untreated stainless steel in service conditions.

Nitric Acid Passivation and How It Works

Nitric acid passivation is the most widely used method for treating stainless steel in industrial water systems. It has a long track record because it is effective at removing free iron and restoring a clean, corrosion resistant surface when applied correctly. In field applications, this approach is often selected for its reliability and predictable results.

The process typically involves placing the stainless steel parts into a nitric acid bath or circulating a nitric acid solution through installed piping and equipment. As the acid contacts the surface, it reacts with iron and other reactive residues. You may see gas bubbles form during this stage. That bubbling is a visible sign of the chemical reaction taking place as contaminants are dissolved and released from the surface.

Concentration and control are critical. Using concentrated nitric acid without proper dilution or monitoring can damage the surface rather than protect it. The acid bath must be matched to the application, material grade, and exposure time. When the chemistry is balanced correctly, nitric acid passivation removes contamination while supporting the formation of a stable passive layer. This is why experienced oversight and clear procedures matter. Done right, nitric acid remains one of the most dependable tools for long-term corrosion control in stainless steel systems.

Citric Acid Passivation as an Alternative Approach

Citric acid passivation is often discussed as an alternative for teams looking to passivate stainless steel with a different chemistry profile. Unlike nitric-based treatments, citric acid relies on chelation to bind and remove free iron from the surface. The end goal is the same, to restore corrosion resistance by allowing the passive layer to form naturally.

From an operational standpoint, citric acid can be easier to handle and dispose of, depending on facility policies and local regulations. It is generally less aggressive toward the material, which can be beneficial for certain grades of stainless steel or sensitive components. However, because it works differently, surface preparation and process control become even more important.

Neither method is universally better. The right choice depends on system design, contamination levels, and performance expectations. In some cases, nitric acid delivers faster, more robust results. In others, citric acid provides adequate protection with fewer handling concerns. What matters most is that the selected process effectively treats the surface and supports long-term corrosion resistance in service.

Sodium Dichromate and Additives in Passivation Baths

In some industrial passivation baths, sodium dichromate is added to enhance the formation of the protective oxide layer. Adding sodium dichromate can improve the corrosion resistance of stainless steel parts, especially in challenging service conditions. The chemical acts as an oxidizing agent, helping the passive layer develop more uniformly across the surface.

However, sodium dichromate is highly toxic and requires strict handling protocols. Safety issues include proper personal protective equipment, ventilation, and waste disposal. Even small mistakes in concentration or exposure can create serious risks for operators and the environment.

Because of this, the use of sodium dichromate demands a careful balance. Facilities must weigh the potential benefits against the added hazards, and consider alternatives when possible. In all cases, the priority should be achieving a uniform passivation layer without compromising operator safety or regulatory compliance.

What a Properly Passivated Stainless Steel Surface Looks Like

A properly passivated stainless steel surface is subtle but noticeable to those who know what to look for. You won’t see a coating or a color change in most cases, but the metal will feel clean and uniform. The goal of the process is to create a continuous passivation layer that protects the underlying metal from corrosion.

The oxide film formed during passivation is very thin, yet highly effective. In some applications, controlled treatments can even produce a slightly thicker oxide layer, which provides extra corrosion resistance. This protective layer is uniform, free of streaks, discoloration, or embedded contaminants. Any deviation from this appearance can indicate incomplete passivation or remaining surface residues.

Teams often learn to recognize success by comparing treated and untreated surfaces. A properly passivated component will maintain its corrosion resistant properties over time, resisting rust and discoloration even under normal operating stresses. This visual and tactile check complements chemical testing, ensuring the passivation process achieved the intended results.

Flash Attack, Rinsing Errors, and Other Common Failures

Even with a well-designed passivation process, failures can occur if key steps are overlooked. One common issue is flash attack, where residual acid on the surface continues reacting after the bath. This can create uneven corrosion or pitting if the component is not neutralized and rinsed promptly.

Rinsing errors are another frequent culprit. A thorough water rinse is essential to remove all chemical residues after passivation. Inadequate rinsing allows acid to linger, which can accelerate corrosion instead of preventing it. Salt spray or high-chloride environments can further exacerbate these weak points, revealing areas where the surface protection is compromised.

Operators often catch early problems by inspecting the surface for discoloration or uneven finishes. Regular attention to rinse quality, immersion timing, and post-treatment handling helps prevent these common failures, ensuring the stainless steel maintains its intended corrosion resistance over time.

Industry Standards and Testing for Passivation

Following industry standards is essential to ensure consistent and reliable passivation. Standard specifications outline the acceptable processes for cleaning, acid treatment, and rinsing, providing clear guidance on how to achieve a uniform passivation layer. These standards exist to protect both operators and the metal, and to guarantee that corrosion resistance meets performance expectations.

Regular verification tests are an important part of standard practice. Measuring free iron levels or using chemical indicators helps confirm that the passivation process has been performed correctly and that the protective oxide layer is intact. Integrating these checks into routine operations ensures the process is controlled, repeatable, and less prone to human error, giving teams confidence that the stainless steel will maintain its corrosion resistance over time.

Why Passivation Matters in Water Treatment Applications

Stainless steel parts are everywhere in water treatment systems. These components are constantly exposed to water, minerals, and dissolved gases, all of which can challenge the metal surface. Without proper passivation, corrosion can develop quietly, undermining system performance and water quality.

A properly passivated surface ensures that stainless steel remains corrosion resistant, even under continuous exposure to aggressive water chemistries. Teams often notice that untreated or poorly passivated components show early signs of rust, pitting, or discoloration, which can lead to leaks, contamination, and costly maintenance. Passivation protects the metal so that it performs reliably over the long term, minimizing downtime and preserving water quality.

Understanding how corrosion interacts with system materials is crucial. Water chemistry directly affects the metal surface, and small issues can escalate if ignored. For guidance on preventing system-level corrosion, operators can refer to strategies for boiler corrosion prevention, galvanic corrosion, and maintaining chemical feed systems to keep surfaces in optimal condition.

Monitoring and Maintaining Passivated Surfaces Over Time

Passivation is not a one-time fix. Maintaining the corrosion resistance of stainless steel requires ongoing attention. Teams should implement a regular schedule for inspecting critical components, checking for discoloration, pitting, or other signs that the protective surface may be compromised. Early detection allows small issues to be addressed before they develop into costly failures.

Routine maintenance also includes verifying that the metal and surface remain clean and free of new contaminants. Even well-passivated stainless steel can lose its effectiveness if exposed to shop dirt, iron particles, or harsh chemicals during operation. Proper handling, storage, and cleaning practices help preserve the protective layer and the integrity of the material over time.

Operators who prioritize monitoring and maintenance find that their systems last longer, operate more efficiently, and experience fewer corrosion-related interruptions. Consistent attention to the surface ensures the passivation process continues to deliver reliable protection for the metal throughout its service life.

Building a Smarter Passivation Strategy for Long-Term Reliability

Developing a reliable passivation strategy starts with understanding the specific needs of your stainless steel workpiece and the environment in which it will operate. Not all parts require the same treatment, and different water chemistries or system designs can affect how well the protective layer forms. Teams should focus on selecting the right process, controlling immersion times, and ensuring surfaces are clean before treatment.

Documentation and consistency are key. Tracking which components have been passivated, the methods used, and the results of post-treatment inspections helps operators identify patterns and prevent repeat issues. When combined with a regular maintenance routine, this approach allows facilities to effectively passivate stainless steel parts and sustain corrosion resistance over time.

Unsure about the best passivation approach for your system or want guidance on optimizing processes for long-term reliability? Contact R2J Chemical Services. Our team can help assess your facility, recommend suitable treatments, and ensure your stainless steel components perform safely and efficiently for years to come.

Frequently Asked Questions (FAQs)

What is the difference between nitric acid and citric acid passivation?

Nitric acid and citric acid are both used to passivate stainless steel parts, but they operate differently. Nitric acid oxidizes the surface to remove free iron and reinforce the passive oxide layer, while citric acid chelates contaminants to achieve similar corrosion resistance. Both improve durability when the surface is properly prepared, though handling requirements and environmental considerations differ.

Can an electrolytic process be used instead of chemical passivation?

Yes, an electrolytic process applies a mild electric current in a controlled solution to enhance the oxide layer on stainless steel. While effective in some cases, it is less common than chemical passivation and typically requires specialized equipment and monitoring for consistent results.

Why does iron on the surface affect passivation?

Iron contamination, even in small amounts, can compromise the passive layer. Free iron reacts differently than stainless steel, creating localized corrosion sites. Thorough cleaning and proper passivation remove these contaminants, ensuring the oxide layer forms evenly and protects the metal effectively.

How can I tell if a stainless steel part is properly passivated?

A properly passivated surface appears uniform, clean, and free of rust, streaks, or discoloration. Chemical indicators and iron detection tests can confirm that the oxide layer has formed correctly, verifying readiness for service in corrosive environments.

Does passivation completely prevent corrosion?

Passivation significantly enhances corrosion resistance but does not make stainless steel immune. Environmental factors, water chemistry, and mechanical damage can still cause corrosion. Regular inspections, proper maintenance, and keeping surfaces clean maximize the protective benefits of passivation.