Industrial Boiler Maintenance: Efficiency and Corrosion Control

Sep 11, 2025Why Industrial Boiler Maintenance Matters

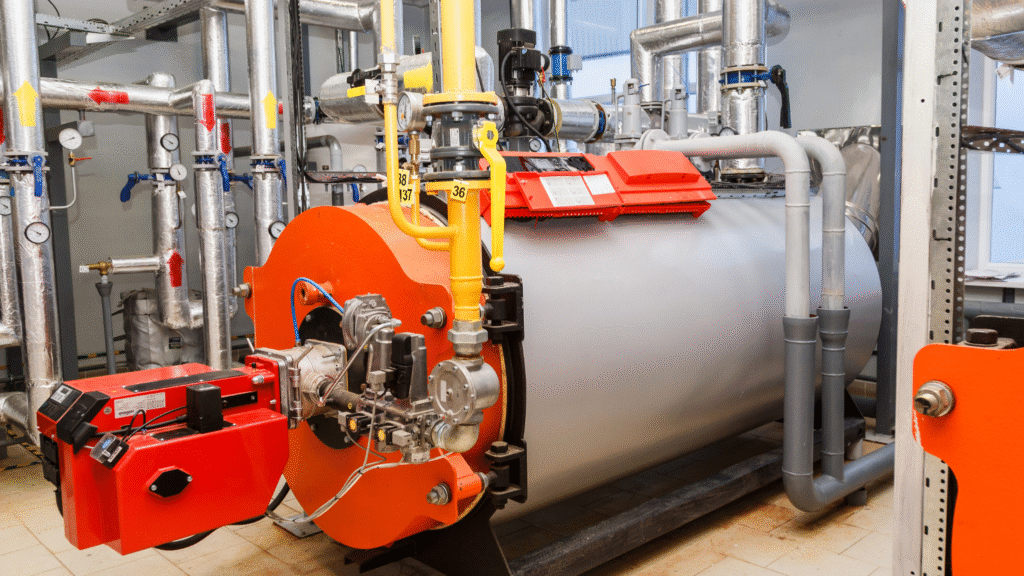

Industrial boilers are the backbone of many facilities. Whether they’re generating hot water for comfort heating or powering steam systems for industrial processes, these complex machines operate under enormous operating stress every day.

Without consistent boiler maintenance, corrosion, scale, and fouling quickly degrade performance. The result? Reduced efficiency, higher fuel consumption, and the risk of costly repairs or downtime. In regulated industrial settings, poor maintenance can also result in violations of safety regulations – putting operators and facilities at risk.

Routine industrial boiler maintenance not only ensures efficient operation but also extends equipment life, reduces fuel costs, and safeguards against emergencies that require boiler repair or full replacement.

Corrosion: The Silent Threat

Corrosion is one of the most common and costly problems in any boiler system. Left unchecked, it can damage:

- Boiler hydronic piping

- Gauge glass and water gauge glass fittings

- Combustion chambers and burner assemblies

- Heat exchangers and flue gas vent piping

Even small leaks can lead to serious failures over time. That’s why a maintenance plan must prioritize monitoring for corrosion and integrating a proper water treatment system to mitigate it.

The Payoff of Preventative Maintenance

Regular inspections and preventive maintenance tasks are proven to deliver measurable results:

- Higher boiler efficiency and optimal efficiency under load

- Reduced downtime and fewer emergency boiler service calls

- Cost savings through extended asset life and improved operational efficiencies

In fact, facilities that adhere to boiler maintenance checklists and log temperature gauge readings consistently show fewer failures and longer intervals between boiler repairs.

Common Boiler Maintenance Challenges vs. Preventative Solutions

| Challenge | Impact | Preventative Action |

| Corrosion in boiler hydronic piping | Leaks, reduced efficiency, unsafe operation | Water treatment, oxygen scavengers, pH control |

| Scale buildup in heat exchangers | Lower heat transfer, increased fuel costs | Boiler blowdowns, dissolved solids monitoring |

| Fouling in combustion chamber | Poor combustion, higher carbon monoxide risk | Clean burner assembly, inspect pilot ignition |

| Failure of safety valves | Risk of overpressure and damage | Check safety valves, perform annual pressure vessel inspection |

Maintenance Frequency at a Glance

| Task | Frequency |

| Daily boiler log (pressure, temperature, water level) | Daily |

| Inspect gauge glass and control systems | Weekly |

| Clean burner’s pilot tube and combustion air piping | Monthly |

| Inspect pressure relief valves, check flue gas and stack temperature | Quarterly |

| Full annual inspection by pressure vessel inspectors | Annually |

Learn more about why consistent attention to corrosion prevention is critical for every facilities.

Understanding Corrosion in Boiler Systems

How Corrosion Develops

Corrosion in an industrial boiler system is typically the result of dissolved gases, acidic conditions, and high stress within the pressure vessel. Oxygen and carbon dioxide are the most damaging:

- Oxygen drives pitting and thinning of metal walls, especially in boiler hydronic piping and condensate systems.

- Carbon dioxide dissolves into water, forming carbonic acid that lowers pH and accelerates wear on pipes, fittings, and valves.

- Poorly managed dissolved solids lead to under-deposit corrosion, where scale traps moisture against metal surfaces.

Left untreated, these conditions weaken critical boiler equipment and drive up the risk of leaks, failures, and even full shutdowns.

Common Corrosion Hotspots

Certain areas of industrial steam boilers and heating systems are more vulnerable than others:

- Combustion chamber: High heat and moisture create a harsh environment.

- Flue gas vent piping and exhaust stack: Corrosive flue gas and condensation damage unprotected surfaces.

- Gauge glass and water gauge glass: Regular monitoring points often degrade faster if water chemistry is off.

- Burner assembly and pilot ignition systems: Corrosion here can lead to misfires and poor fuel efficiency.

By focusing regular inspections on these hotspots, boiler operators can catch corrosion early before it turns into costly repairs.

The Impact of Corrosion on Efficiency

Corrosion isn’t just a maintenance issue – it directly lowers boiler efficiency. Metal loss, leaks, and scaling reduce heat transfer, forcing the boiler system to burn more fuel to achieve the same output. This leads to:

- Higher fuel consumption and operating costs

- Increased downtime for boiler service and boiler repair

- Reduced equipment lifespan

Facilities that neglect corrosion prevention often face a cycle of reduced efficiency, frequent boiler repairs, and compliance issues with safety regulations.

Types of Boiler Corrosion

| Type | Cause | Impact | Prevention |

| Oxygen pitting | Dissolved oxygen in boiler feedwater | Localized metal loss, leaks | Oxygen scavengers, deaeration |

| Acidic corrosion | Low pH from CO₂ in condensate | Pipe wall thinning, pitting | pH control, neutralizing amines |

| Galvanic attack | Dissimilar metals in contact with water | Accelerated corrosion on less noble metal | Material selection, cathodic protection |

| Under-deposit | Deposits trapping oxygen/moisture on metal | Pitting under scale, tube failures |

Dive deeper into how water chemistry drives corrosion and learn more about How to Prevent Corrosion in Boilers Through Water Treatment.

Preventative Maintenance Tasks and Boiler Checklists

Why Checklists Matter

Boilers are complex machines with dozens of interdependent parts. Without a structured approach, critical details can be overlooked. A boiler maintenance checklist provides consistency, ensuring that boiler operators and facility managers address daily, weekly, monthly, and annual needs. By logging data and confirming completion of routine maintenance tasks, facilities reduce the likelihood of costly repairs, downtime, or compliance violations.

Daily and Weekly Tasks

Some maintenance tasks need attention every day or week to ensure safe boiler operation:

- Recording temperature gauge readings and water levels in a boiler log

- Checking gauge glass and water gauge glass for clarity and accuracy

- Inspecting control systems for alarms or irregularities

- Ensuring the burner’s pilot tube and pilot ignition are functioning

- Confirming fuel system supply (whether natural gas or fuel oil)

Weekly, operators should also:

- Inspect safety valves and test boiler relief valves for leaks

- Check for abnormal vibrations in pumps, motors, and moving parts

- Inspect boiler room conditions: ventilation, combustion air piping, and drains

Monthly and Quarterly Tasks

A more thorough look each month includes:

- Cleaning the burner assembly and combustion chamber to avoid fouling and carbon monoxide risks

- Testing control panels and float switches in condensate systems

- Checking stack temperature and exhaust stack conditions for signs of fouling

- Inspecting flue gas vent piping for leaks or corrosion

Quarterly reviews may include:

- Verifying pressure relief valves

- Inspecting boiler hydronic piping for leaks or corrosion

- Testing sensors and mechanical alternators for proper function

Annual Inspections

Every year, a comprehensive inspection by certified pressure vessel inspectors should be scheduled. Annual maintenance often includes:

- Internal inspection of pressure vessel integrity

- Verifying safety valves, boiler pressure controls, and water treatment system performance

- Evaluating heat exchanger and condensing boiler components for scaling or cracks

- Confirming compliance with local safety regulations

Boiler Maintenance Checklist by Frequency

| Frequency | Preventive Maintenance Tasks |

| Daily | Record boiler log, check water level, gauge glass, and temperature readings |

| Weekly | Inspect safety valves, test boiler relief valves, check control systems |

| Monthly | Clean burner assembly, inspect combustion air piping, check exhaust stack |

| Quarterly | Verify pressure relief valves, inspect hydronic piping, review stack temperature |

| Annually | Full annual inspection, internal pressure vessel review, check heat exchangers |

Why Regular Boiler Maintenance Pays Off

Facilities that follow these structured schedules see clear benefits:

- Improved boiler efficiency and fewer energy losses

- Lower fuel costs and optimized fuel consumption

- Extended service life of boiler equipment

- Fewer emergency shutdowns and boiler service calls

Learn more about long-term efficiency strategies in optimizing boiler system performance.

Water Treatment’s Role in Boiler Maintenance

Why Water Chemistry Matters

Even the most thorough inspection schedule won’t prevent corrosion or scaling if the boiler water chemistry is out of balance. A reliable water treatment system is the foundation of corrosion prevention. Poor chemistry accelerates tube failures, fouls heat exchangers, and drives up fuel costs as deposits insulate surfaces and reduce heat transfer.

Core Elements of Treatment

A complete treatment program focuses on controlling gases, solids, and chemistry within the boiler. Key practices include:

- Oxygen scavengers to eliminate dissolved oxygen that causes pitting in boiler feedwater and condensate systems.

- pH adjustment to maintain neutral or slightly alkaline conditions that reduce acidic attack.

- Boiler blowdowns to remove concentrated dissolved solids and sludge from the system.

- Chemical treatment to protect metal surfaces and disperse scale-forming minerals.

Well-run treatment programs directly support boiler efficiency and help operators avoid emergency downtime or costly repairs.

Treatment Challenges and Solutions

Improper treatment often shows up as corrosion in gauge glass fittings, deposits inside flue gas vent piping, or scaling in hot water and steam generation components. These failures shorten equipment life and drive up operating expense. By working with a qualified water treatment company, facility teams can catch these issues early, adjust chemical feed, and extend the lifespan of critical boiler equipment.

| Cause of Problem | Impact on Boiler System | Treatment Approach |

| Dissolved oxygen | Pitting, leaks, tube damage | Oxygen scavengers, deaeration |

| High dissolved solids | Scale, reduced boiler efficiency | Controlled boiler blowdowns |

| Low pH / carbonic acid | Corrosion in condensate return lines | Neutralizing amines, pH conditioning |

| Silica and hardness minerals | Fouled heat exchanger tubes | Scale inhibitors, dispersants |

Learn more about how oxygen scavengers protect boilers and help maintain optimal boiler system performance.

Troubleshooting and Boiler Repairs

Early Warning Signs of Boiler Problems

Even with a solid maintenance plan, issues will arise in any industrial boiler. Spotting them early can prevent shutdowns or costly repairs. Operators should watch for:

- Abnormal temperature gauge readings or rising stack temperature

- Excessive vibration in pumps, motors, or control systems

- Leaks in boiler hydronic piping or condensate systems

- Irregular boiler pressure or safety alarms

- Odors that may indicate carbon monoxide leaks in the combustion chamber

Catching these indicators quickly can mean the difference between a minor adjustment and an expensive boiler service call.

When Boiler Repair Is Required

Some problems require immediate intervention. These include:

- Malfunctioning safety valves or pressure relief valves

- Corroded flue gas vent piping or exhaust stack damage

- Burner issues, such as a fouled burner assembly or failed pilot ignition

- Fouled heat exchanger tubes limiting heat transfer

- Severe corrosion in water gauge glass fittings

In these cases, scheduling professional boiler repair or replacement of components is critical to protect operators and meet safety regulations.

Reducing the Likelihood of Costly Repairs

The best way to minimize downtime is still preventative maintenance. Regular inspections, logged data, and consistent water treatment prevent the majority of premature failures. Facilities that keep up with annual inspections and implement preventive maintenance tasks rarely face the type of emergency shutdowns that drive operating expenses sky-high.By maintaining clear maintenance logs and integrating boiler blowdowns into daily routines, operators ensure safe operation while extending asset life.

Linking Repairs Back to Water Treatment

Most corrosion-related failures trace back to poor water chemistry. Issues like scaling, pitting, or tube damage in steam boilers and condensing boilers often emerge when boiler feedwater quality isn’t properly monitored. Partnering with a trusted water treatment company ensures the system is protected from within – making emergency boiler repairs far less likely.

Learn how boiler blowdowns support efficiency and reduce the risk of expensive breakdowns for your facility.

Best Practices for Boiler Maintenance and Corrosion Control

Building a Reliable Maintenance Plan

The strongest defense against corrosion and efficiency loss is a documented maintenance plan. Facilities should establish structured schedules for regular inspections, log boiler operation data daily, and prioritize preventative maintenance over reactive repairs. When checklists are built into daily operations, boiler operators reduce surprises and extend the life of critical boiler equipment.

Preventative programs should also account for all supporting infrastructure: fuel systems, boiler hydronic piping, combustion air piping, and control systems. Skipping these components often leads to undiagnosed failures that compromise both safety and efficiency.

Aligning Maintenance with Water Treatment

Boilers are only as reliable as the water that feeds them. A modern water treatment system prevents corrosion, scale, and sludge accumulation that damage tubes, valves, and pressure vessels. Treatment plans should always integrate:

- Boiler blowdowns to control dissolved solids and sludge

- Oxygen scavengers to protect feedwater and condensate return lines

- pH conditioning and dispersants to maintain stable chemistry

Operators who invest in regular maintenance alongside robust water chemistry achieve the best balance of reliability and efficiency. Learn more about how boiler water treatment supports corrosion prevention and system protection.

Why Partnering with Experts Matters

Even with diligent staff, complex industrial steam boilers demand expertise. Partnering with a trusted water treatment company ensures your maintenance strategy is backed by chemical knowledge, testing, and responsive support. R2J can help you with:

- Reduced emergency calls and fewer costly repairs

- Long-term cost savings through optimized efficiency

- Compliance with safety codes and safety regulations

- Confidence that all preventive maintenance tasks are being met in a technically competent manner

Contact R2J today to schedule a consultation and strengthen your boiler maintenance plan with proven corrosion prevention strategies.

Frequently Asked Questions (FAQ)

Why is corrosion prevention important in industrial boilers?

Corrosion weakens pressure vessels, degrades pipes, and reduces boiler efficiency. Preventing it avoids leaks, downtime, and dangerous failures.

What’s included in regular boiler maintenance?

Tasks range from daily boiler logs and gauge checks to annual inspections of safety valves, combustion chambers, and heat exchangers.

How often should safety valves and pressure relief valves be checked?

At least quarterly, with a full review during the annual inspection. Failures here are among the most dangerous boiler risks.

How does water treatment protect a boiler system?

Balanced chemistry prevents scale and corrosion, protecting boiler feedwater, condensate systems, and critical components like gauge glass and tubes.

What are the risks of poor boiler water treatment?

Untreated water leads to fouling, scaling, and corrosion. This causes reduced efficiency, higher fuel costs, and premature boiler repair.

What role do boiler blowdowns play in efficiency?

Boiler blowdowns remove concentrated solids and prevent sludge buildup. This protects tubes, maintains optimal efficiency, and lowers chemical demand.

Can maintenance really deliver cost savings?

Yes. Facilities that follow boiler maintenance checklists and integrate water treatment consistently see lower fuel consumption, fewer shutdowns, and extended equipment life.