Modern Water Treatment Technology for Clean, Safe Water

Aug 01, 2024Clean, safe water is the backbone of every facility, industry, and community. Modern water treatment technology goes far beyond simple sand filters, offering advanced solutions that protect drinking water, enhance water quality, and maintain equipment reliability. From municipal systems supplying entire cities to industrial facilities handling complex wastewater, effective water treatment ensures safety, efficiency, and sustainability. Understanding how these systems work and the innovations behind them helps operators and facility managers make informed decisions that keep water flowing safely and systems running smoothly.

Understanding Water Treatment Systems

Every effective water treatment system starts by examining the source water. Raw water often contains suspended solids, dissolved minerals, and occasionally biological matter. Hard water, high in calcium and magnesium, can scale pipes, reduce equipment efficiency, and affect water quality if left untreated. Operators often catch early issues by monitoring mineral levels and sediment buildup.

Water treatment systems use a combination of approaches to address these challenges. Physical methods, like filtration, remove larger particles and suspended solids. Chemical treatments adjust pH, neutralize contaminants, and control microbial growth. Biological treatment employs microorganisms to safely break down organic compounds, producing clean, treated water ready for use in industrial processes or for drinking water distribution.

For guidance on identifying and managing hard water, see our guide on what is hard water.

Core Water Treatment Technologies

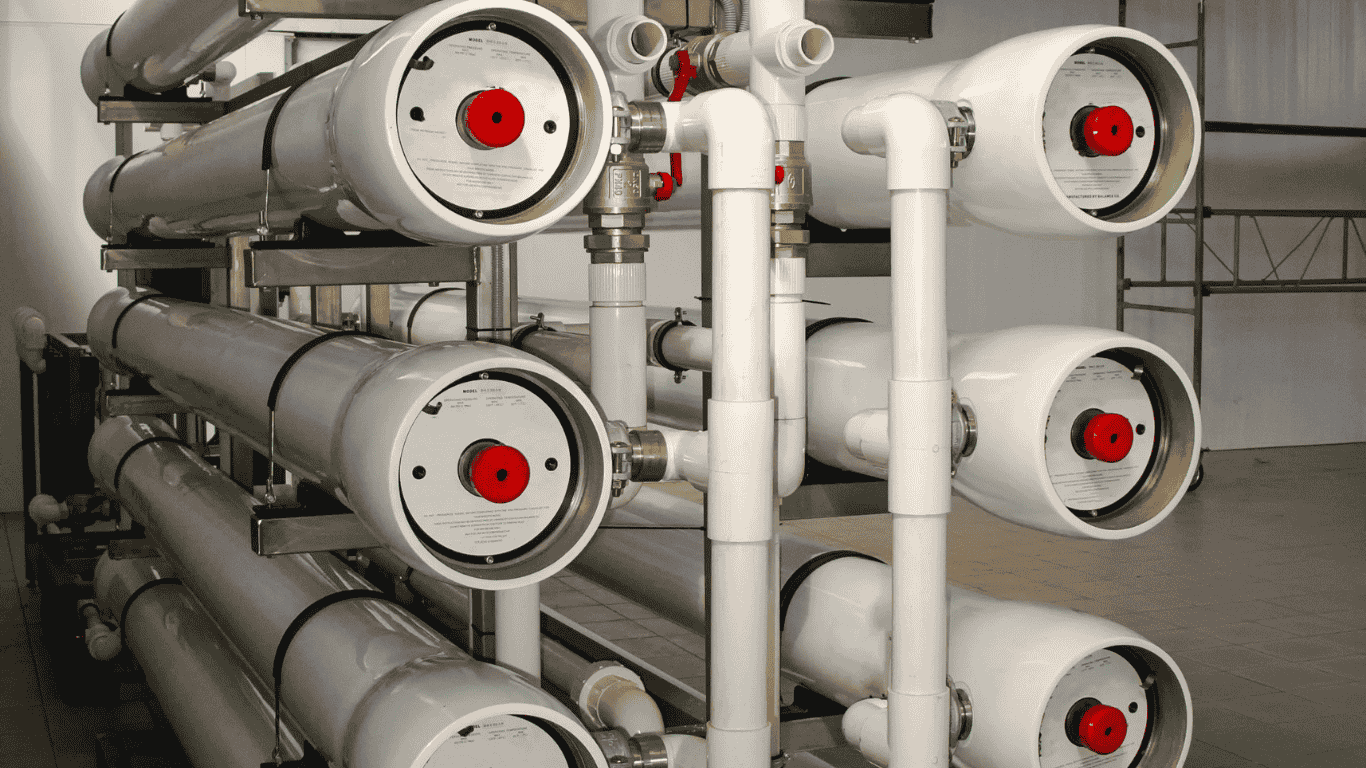

Modern water treatment technology combines multiple methods to remove contaminants and ensure safe, high-quality water. Filtration technologies play a central role. Membrane filtration and reverse osmosis separate dissolved salts, heavy metals, and fine particles, producing water suitable for industrial or municipal use. Granular activated carbon (GAC) and activated carbon filters remove chlorine, odor compounds, and organic compounds, improving taste, smell, and overall water quality.

Chemical treatments are another essential layer. Chemical disinfectants, chlorine dioxide, hydrogen peroxide, and sodium hydroxide control microbial growth, adjust pH, and break down volatile organic compounds. These processes work in tandem to protect equipment, maintain consistent water quality, and reduce biological risks.

Biological processes harness beneficial microorganisms to safely degrade organic pollutants. Proper monitoring prevents unwanted biofilm formation, which can compromise system efficiency and water quality. For more on managing microbial challenges, see our post on biofilm in water.

Advanced treatment technologies like advanced oxidation processes (AOPs) tackle contaminants that conventional systems cannot, providing high-purity water for sensitive applications. Facilities investing in these technologies often see long-term cost savings, sustainability benefits, and improved operational reliability. Explore strategies for long-term solutions in our guide on sustainable water treatment.

Practical Applications in Industrial & Municipal Settings

Modern water treatment technology plays a critical role in both industrial and municipal settings. Facilities managing industrial wastewater often face complex mixtures of organic compounds, heavy metals, and oils. Treatment systems combine physical, chemical, and biological methods to remove contaminants while protecting equipment and meeting regulatory standards. Properly treated water supports sensitive manufacturing processes, including food production, pharmaceuticals, and electronics.

Municipal systems focus on drinking water treatment for safe public supply. Filtration removes suspended solids, activated carbon manages taste and odor, and disinfection ensures pathogen-free water. Operators constantly monitor water quality to maintain safe water supplies, adjusting processes to handle seasonal changes or industrial discharge. Advanced methods, such as reverse osmosis, also help remove dissolved salts and trace contaminants when high-purity water is required.

Sustainable practices allow for water reuse, reducing fresh water demand and environmental impact. Facilities can repurpose treated water for cooling systems, irrigation, or industrial processes. For facilities handling brackish sources, specialized solutions exist; learn more about these strategies in our Brackish Water Treatment guide.

Monitoring Water Quality & System Efficiency

Maintaining consistent water quality relies on careful monitoring of key water quality parameters. Operators track pH, turbidity, total dissolved solids (TDS), temperature, and residual disinfectant levels to ensure treatment systems function effectively and produce safe, reliable water.

Regular checks allow teams to spot early signs of scaling, corrosion, or microbial growth. Small deviations in these parameters can indicate issues with filtration, chemical dosing, or biological treatment processes. Addressing them quickly prevents costly downtime and protects equipment longevity.

Modern systems often incorporate sensors and automated monitoring tools, reducing manual oversight while improving accuracy. Facilities using automation can detect anomalies in real time and make adjustments immediately. Learn more about optimizing system performance through advanced monitoring in our Water Treatment Automation guide.

Addressing Challenges in Water Treatment

Even the most advanced water treatment technology faces operational challenges. Variations in influent water quality: caused by rainfall, industrial discharge, or seasonal changes can affect system performance, requiring adjustments to chemical dosing and filtration rates.

Managing other contaminants such as heavy metals, suspended particles, and organic pollutants is critical to prevent equipment damage and maintain water quality. Biological issues, like unwanted biological growth, can form biofilm, clog filters, and reduce efficiency. Regular monitoring and proper maintenance help operators stay ahead of these risks.

Treatment systems also generate spent media and residual waste that must be safely handled or replaced. Maintaining a consistent treatment process through scheduled inspections, equipment cleaning, and timely media replacement ensures optimal performance, reduces downtime, and extends the life of both water and equipment.

Steps to Optimize Your Water Treatment Technology

Optimizing your water treatment technology starts with understanding your source water. Evaluate for hard water, suspended solids, and other contaminants to determine the right combination of filtration, chemical dosing, and biological treatment.

Next, monitor key water quality parameters consistently. Tracking pH, turbidity, and total dissolved solids ensures your water treatment process stays on track. Timely maintenance, such as replacing spent media and cleaning filters, keeps systems running efficiently and prolongs equipment life.

Finally, implement a strategy for sustainable treated water use. Reuse opportunities, like cooling or irrigation, can reduce costs and environmental impact. Need guidance on building a tailored program that improves water quality, protects equipment, and ensures reliable operations? Partner with our team at R2J Chemical Services to develop a solution suited to your facility’s needs.

Frequently Asked Questions (FAQs)

What types of contaminants can modern water treatment systems handle?

Water treatment systems remove organic contaminants, inorganic contaminants, suspended solids, and microbial pathogens. Advanced technologies, like membrane separation processes and reverse osmosis RO, target small molecules and heavy metals, while chemical coagulants and ozone gas treat broader waste streams.

How does UV disinfection improve water quality?

UV light and UV disinfection use high-intensity UV lamps to inactivate pathogenic bacteria and viruses without leaving chemical residues. UV oxidation breaks down natural organic matter and volatile organic compounds, ensuring safe drinking water treatment and reducing water pollution risks.

What role do membranes and filtration play?

Membrane processes, including semi-permeable membranes, physical adsorption, and ion exchange, remove organic pollutants, vinyl chloride, and dissolved salts. Filter media capture fine particles and improve water clarity for industrial and municipal applications.

How do treatment plants manage varying water sources?

Water treatment plants adjust for influent water quality, temperature, and fluctuating contaminants. Techniques like air stripping, chemical dosing, and concentrated solutions target various contaminants, ensuring consistent treated water in distribution systems.

Can treated water be reused safely?

Yes. Facilities repurpose treated water for cooling water, irrigation, or industrial processes. Monitoring molecular weight, short half-life chemicals, and treatment effectiveness ensures safety and regulatory compliance, even in developing countries or sensitive applications.